Our tool for managing your permission to our use of cookies is temporarily offline. Therefore some functionality requiring your consent to use of cookies may be missing.

LET'S DO MORE WITH LESS.

We MINImise wherever we can to deliver a more reliable and sustainable driving experience. By MINImise, we mean reducing waste, energy and CO2 emissions per vehicle throughout the life cycle to realise our vision of a purer dynamism. We are committed to pioneering a balance that embraces renowned MINI performance and iconic design with sound environmental credentials. And by reducing our impact, we enable you to reduce yours.

MEET URBAN-X BY MINI.

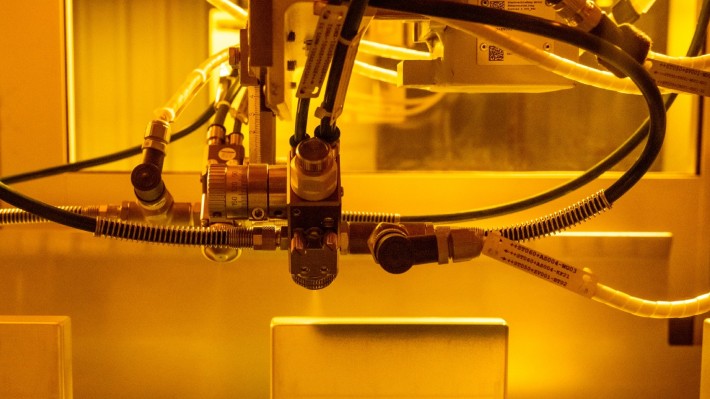

Founded by MINI in 2016, URBAN-X has now established itself as a leading urban technology startup platform. It provides tailored support to early-stage entrepreneurs who aim to improve urban life with their bold climate technology solutions.

In just seven years, URBAN-X has already partnered with over 100 startups in areas such as mobility, buildings, energy and community. It has helped them develop their innovative, sustainable solutions, accelerate growth and lay the foundations for business success.

TRADITION IN TRANSITION.

The new all-electric MINI family heralds a new era of a more sustainable, connected MINI while still daring to be different. By going leather-free with reduced chrome levels and integrating advanced digitalisation, it reflects how MINI is reinventing itself for its all-electric future.

Designed for recycling.

DASH AND DOOR PANELS FROM RECYCLED FABRICS

As part of our commitment to increasing the use of sustainable materials, the dashboard and armrests in our doors are now fitted with a quality knitted textile made of recycled polyester yarn. Following an innovative process that turns 92% of recycled polyester fibres into a 2D flat woven fabric, we use then this textile for the knitted parts of the dashboard and the door panels. It lends the interior a sense of warmth and also perfectly serves as a screen for digital projections. The process reduces our footprint considerably as it uses around 98% less water than cotton, and it reduces CO2 emissions by around 80% compared to conventional polyester processing.

ON THE ROAD TO ZERO.

80% CO2

fewer emissions by 2023

11,500 solar Panels

on the roof of the MINI Oxford plant generate more than 3 megawatts

29 mins

to charge from 10%–80% with a DC fast charger

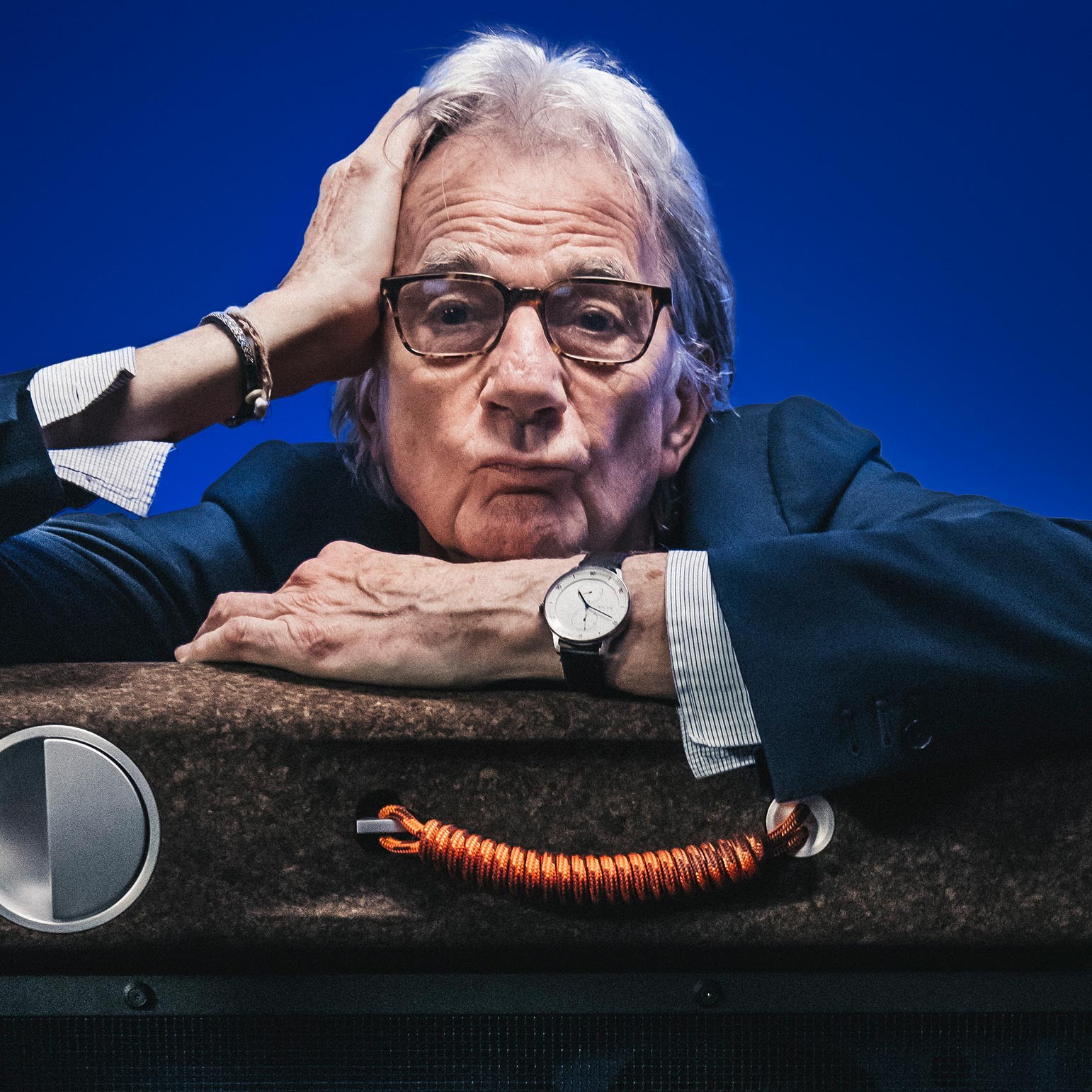

SUSTAINABLE VOICES.

Everyone can play their part in making MINI sustainable. In our interview series, we highlight the sustainable contribution made by a wide range of MINI people – and the motivation that inspires them.

HOW TO BECOME A SUSTAINABLE MINI DRIVER.

How can drivers help the environment?

What can you do to make your daily drive more sustainable? Eco-friendly driving practices enable you to help the environment. They can also help save you money and stay safe on the road. Here is a closer look at some easy ways to make a change for the better – from before you buy your car right through to maintenance and upkeep.

INSPIRATION. IT’S WHAT DRIVES US.

Projects, stories and collaborations – inspired by our motivation to do better, and to do more – for all of us, and the planet, too.

Things we're often asked.

The key raw materials of the high-voltage storage are cobalt, lithium, graphite and nickel. The shell of the high-voltage battery is made of aluminum. MINI (BMW Group) is committed to developing a supply chain that is responsible, sustainable and one that meets our own high ethical and human rights standards. Each nominated supplier must provide information on the implementation of environmental, social and governance standards including respect for human rights and the prohibition of forced labour.

We work closely with key raw material suppliers to ensure that all materials are responsibly sourced both to protect and enhance the environment, and to ensure the safety and well-being of the employees at any point along the supply chain. We also continue to streamline logistics operations to reduce impacts from transporting components to our plants.

The social and environmental due diligence obligations associated with sourcing components, materials and other services are set out for our suppliers in our contractually binding sustainability standards. When we identify risks at our direct suppliers, we respond to these with preventive and corrective measures. And we do the same for our indirect suppliers on an ad-hoc basis. These measures have been systematically anchored in our processes.We are also working on reducing the consumption of raw materials and increasing the use of secondary materials.

Gaining maximum visibility into our supply chain helps us identify issues on the ground and deal with them effectively, often in partnership with our suppliers and other stakeholders. The increase of transparency and resource efficiency in our supply chains is based on compliance with environmental and social standards as defined in the BMW Group sustainability standard. Each supplier must consider these requirements in its offer. Furthermore, we are guided by international standards such as the guidelines of the UN Global Compact Initiative (Davos, 01/99) and the "Declaration on Fundamental Principles and Rights at Work" (Geneva, 06/98), the International Labor Organization (ILO) and their due diligence process with the requirements of the "UN Guiding Principles on Business and Human Rights.”

The greenness of any electric car ultimately depends on the source of the mains electricity that feeds the battery. Another aspect of the lifetime CO2 footprint is the energy used to manufacture the battery pack. With this in mind, tests showed that if the MINI Cooper SE is charged using a renewable electricity mix, it breaks even or has ‘worked off’ the CO2 released during its manufacturing after approximately 19,000 km. Over a full life cycle, the emissions of a MINI Cooper SE are 40% (EU mix) and 70% (renewable mix) compared to that of a petrol-driven MINI Cooper S. That means, using typical daily driving distances, it takes just 12 months of driving for the MINI Cooper SE to offset the extra global warming emissions from producing it.

WE'RE on the road to Electric.

Be part of the change.

Explore the benefits of embracing the new electric lifestyle. See how much you’ll save, how often you’ll need to charge, and how easy electric driving can be.

MEET THE NEW ALL-ELECTRIC MINI FAMILY.

It’s the beginning of a new era. The new all-electric MINI family offers hallmark driving excitement with an all-electric drivetrain and an immersive digital user experience.